ON DEMAND WEBINAR

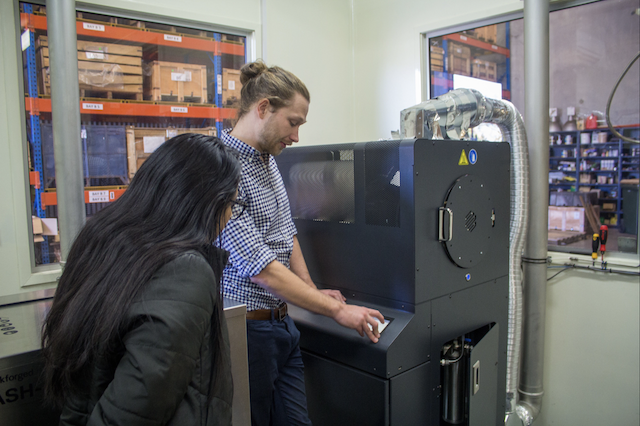

Virtual Factory Tour with Markforged Customer Retrocast

Join us for a on demand LIVE broadcast from Markforged customer Retrocast’s factory in QLD, Australia for a detailed virtual factory tour and demonstration of reverse engineering — from 3D scanning and CAD to the Markforged 3D printing.

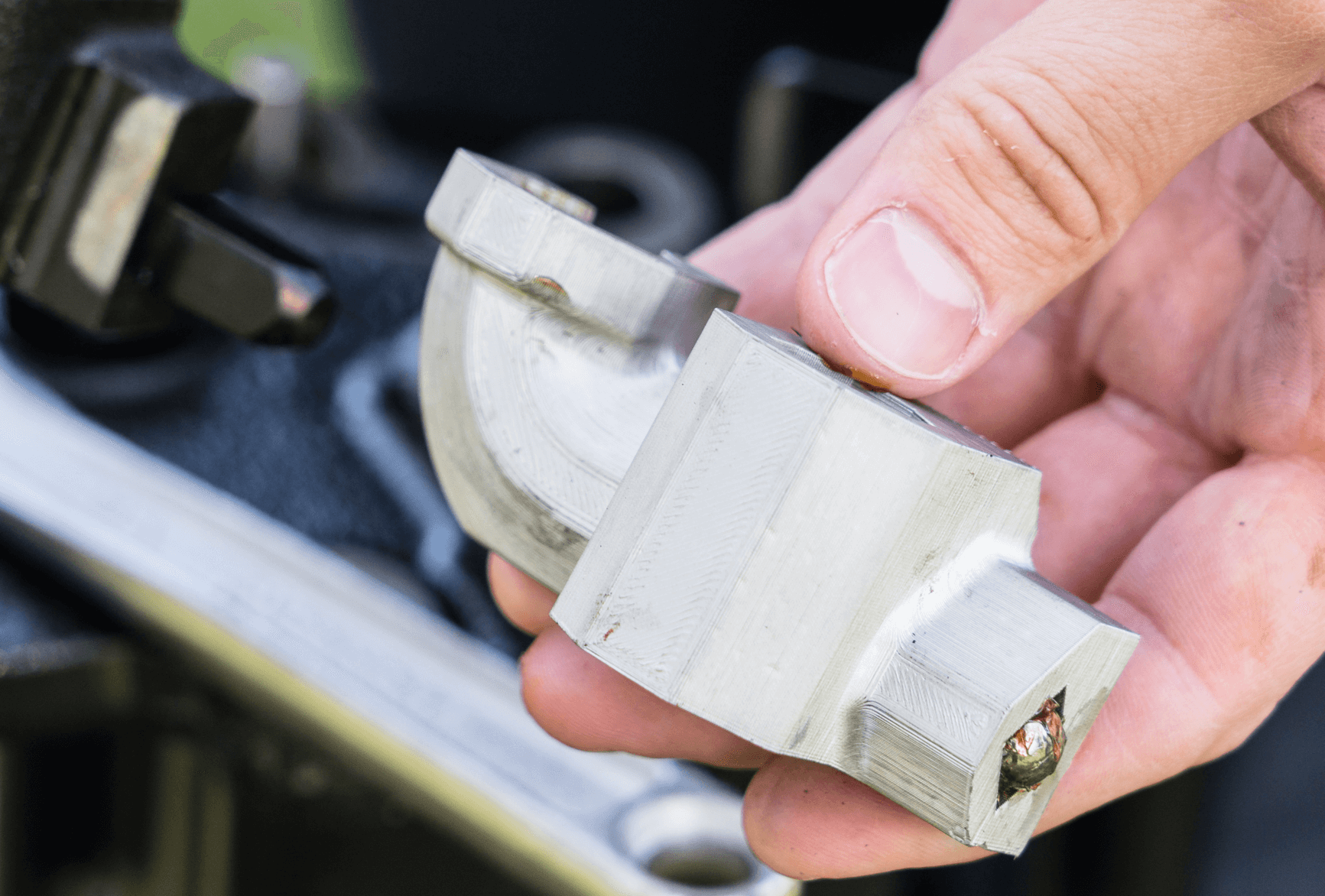

Learn best practices for how you can benefit from reverse engineering workflows. Retrocast is taking control of its supply chain and reducing reliance on third parties by transitioning to reverse engineering manufacturing, leveraging a digital workflow and the Markforged Metal X system to 3D print metal parts.

Join us to learn about:

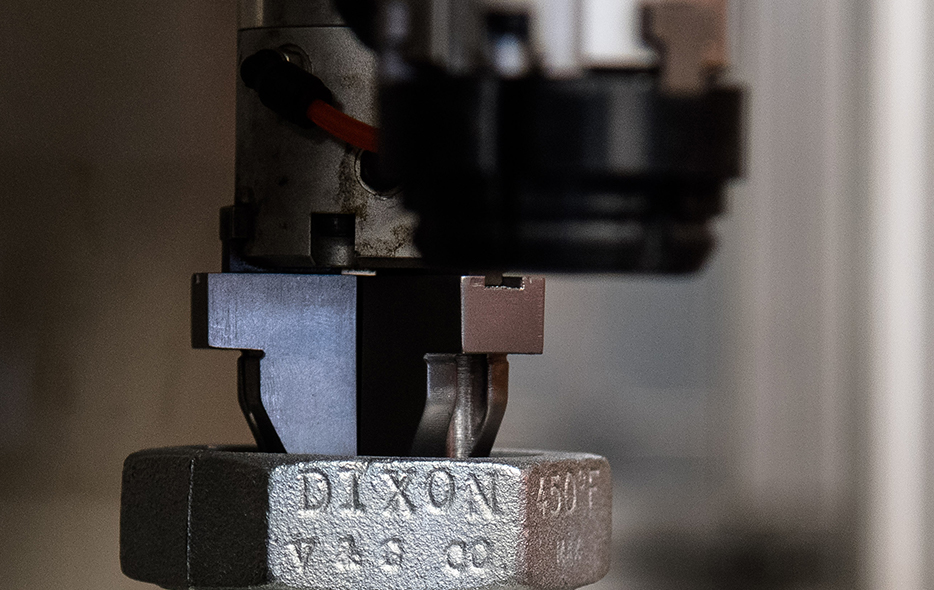

- How you can go from 3D scanning and using CAD to a metal 3D printed part

- What type of parts you can produce with the Metal X system

- Retrocast’s experience in building in-house production capabilities with the Metal X system

- How moving from traditional manufacturing to additive manufacturing helps to reduce cost

Featured Speakers:

Peter Glennie

Managing Director, Retrocast

Anthony Rosengren

Applications Engineering, Markforged

Richard Elving

Director, Markforged APAC

Register Now

On Demand Webinar

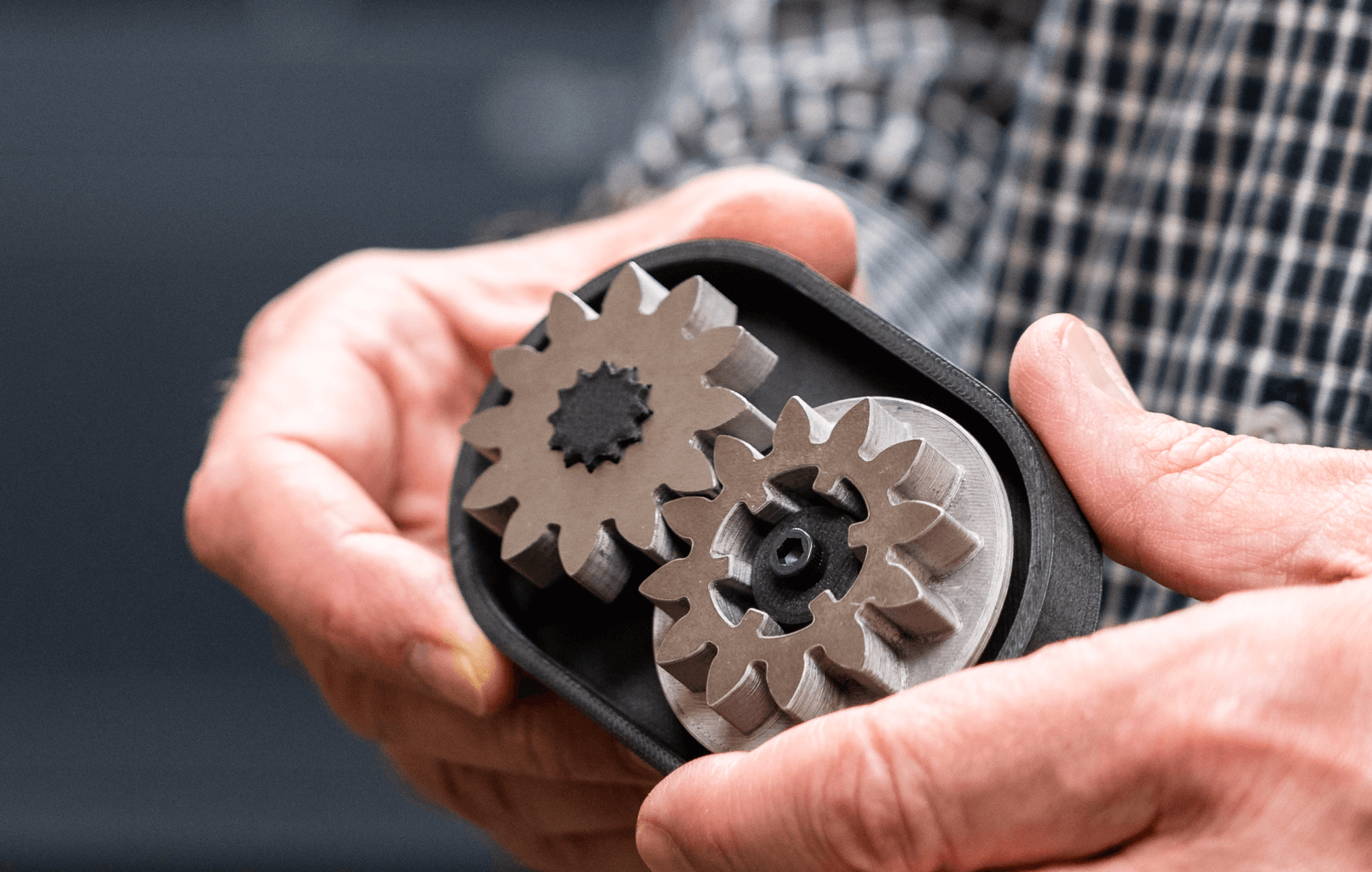

3D print strong parts

Markforged specializes in 3D printers for high-strength applications. Our range of metal and composite 3D printers yields parts in stainless steel, tool steel, carbon fiber, fiberglass, inconel, titanium, and more.

Open up CNC bandwidth for revenue-generating parts

Lean Machine now has 5x lower use of in-house CNCs for tooling and fixtures, using Markforged technology to create parts that can’t be achieved by other processes. The CNC operators now run the machines full time purely for production work instead, with fewer interruptions from Engineering

Minimize lead time from prototype to production part

With an in-house Markforged 3D printer, you are in greater control of when your parts are made, reducing the risk of unexpected supply chain delays.

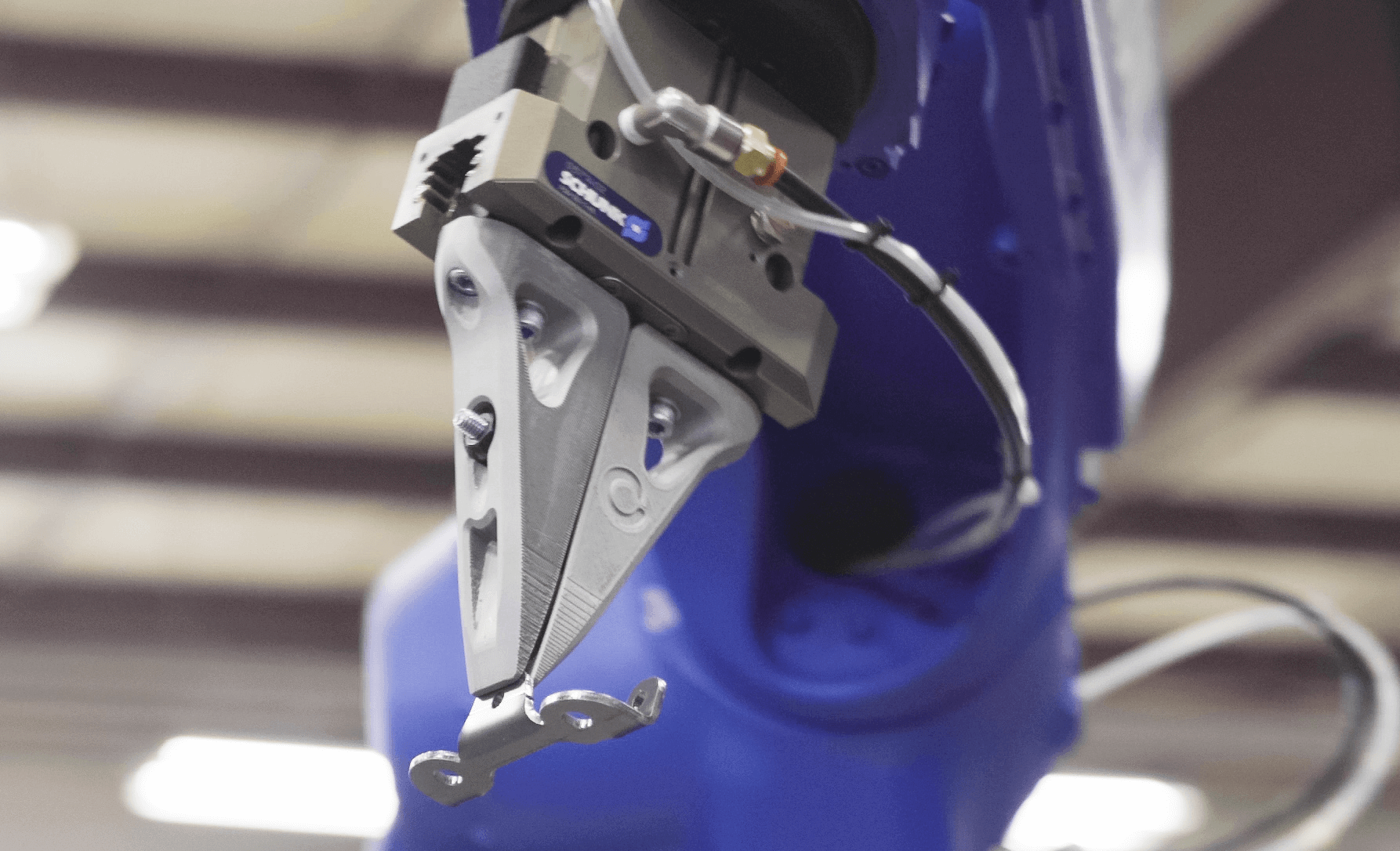

Unlock design freedom and 3D print geometrically complex parts

3D print parts that were previously too complex or costly to machine. By adopting Markforged, Stanley Black & Decker consolidated a four-piece assembly into one 3D printed part that otherwise could not have been made without assembly.